Lean Production Fundamentals Explaineds

Wiki Article

Some Known Details About Lean Production

Table of ContentsThe 6-Second Trick For Manufacturing3 Easy Facts About Manufacturing Industries ShownA Biased View of ManufacturingLean Production Things To Know Before You BuyExcitement About Hon Hai PrecisionThe Best Strategy To Use For Mfg

The text on this web page is an example from our complete White Paper 'Injection Moulding for Buyers' - * Sample text * - for full overview click the download switch over! Introduction This guide is planned for people who are looking to resource plastic mouldings. It provides a much required understanding right into all that is entailed with developing plastic components, from the mould tool needed to the moulding process itself.If you intend to explore further, the overview covers types of mould devices, along with unique ending up procedures such as colours & plating. Words that are highlighted can be discovered in the reference in the appendix ... Part I: Moulding: The Basics The Advantages of Shot Moulding Plastic injection moulding is a very exact procedure that uses a number of advantages over other plastic processing approaches.

Precision is ideal for very intricate parts. You can hold this moulding in the palm of your hand and also it has managers, ribs, steel inserts, side cores as well as holes, made with a moving closed off function in the mould device.

The Greatest Guide To Oem

The 3-Minute Rule for Manufacturing

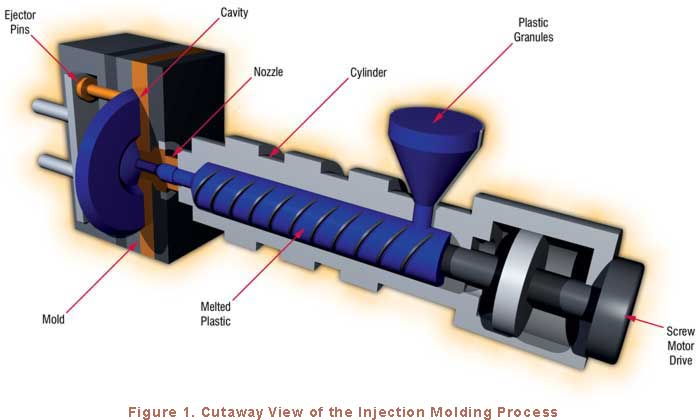

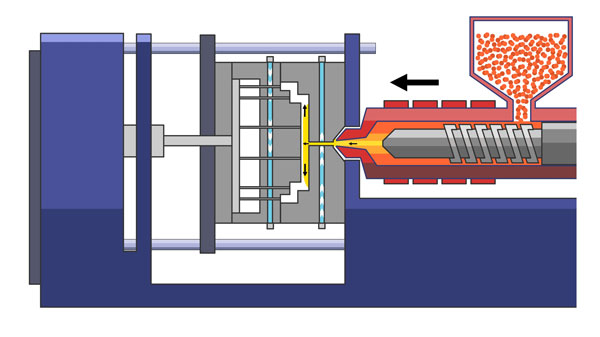

from material feed Product melting; material injection; shot time and ejection as well as the re-closing of the mould tool ready device prepared next cycle. Draft angles - The walls of a moulded part ought to be a little tapered in the direction in which the component is expelled from the mould tool, to enable the part to be ejected conveniently.Ejector stroke - The pressing out of ejector pins to eject the moulded part from the mould tool. Ejector stroke speed, length as well as timing requires to be meticulously regulated to avoid damages to the ejectors as well as mould tool, yet at the very same time make the moulding cycle as short as feasible.

Rumored Buzz on Additive Manufacturing

Ribs - When a plastic part has thin wall surfaces, ribs are contributed to the style to make the slim wall surfaces more powerful Side cores - Side activity which generates a feature on a moulded component, at an opposing angle to the regular opening instructions of the mould tool. lean production. The side core requires to be able to pull back as the plastic component can not be expelled otherwise.

Walls - The sides of a moulded component The text on this page is a sample from our complete White Paper 'Shot Moulding for Customers'.

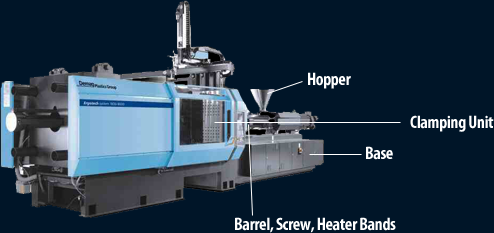

Injection moulding is commonly utilized for making a range of parts, from the tiniest elements to whole body panels of automobiles. Shot moulding uses a special-purpose maker that has 3 components: the shot unit, the mould and the clamp.

The smart Trick of Die Casting That Nobody is Discussing

, with the volume utilized of the previous being significantly higher.: 13 Thermoplastics are prevalent due to qualities that make them very suitable for shot moulding, such as convenience of recycling, versatility for a large selection of applications,: 89 and also ability to soften as well as flow on heating.In multiple cavity moulds, each dental caries can be similar and also create the very same parts or can be unique and develop multiple different geometries throughout a single cycle.

The screw supplies the raw product forward, mixes as well as homogenises the thermal as well as viscous distributions of the polymer, and decreases the needed home heating time by mechanically shearing the material and also including a substantial quantity of frictional heating to the polymer. The material feeds ahead with a check valve as mfg well as collects at the front of the screw right into a volume called a shot. When enough material has actually collected, the material is compelled at high pressure and also speed into the component creating dental caries. The exact quantity of contraction is a feature of the material being used, and can be reasonably foreseeable. To stop spikes in pressure, the process useful link normally utilizes a transfer setting representing a 9598% complete dental caries where the screw changes from a consistent velocity to a consistent stress control.

More About Plastic Manufacturing

The packing pressure is used up until the gate (tooth cavity entry) strengthens. Due to its small size, the entrance is usually the very first place to strengthen through its whole thickness.: 16 Once the gateway solidifies, no even more product can get in the dental caries; accordingly, the screw reciprocates and gets material for the next cycle while here the material within the mould cools down so that it can be expelled as well as be dimensionally steady.Report this wiki page